Don't Risk It: These 3 Power Tool Safety Systems Can Prevent Injury and Damage

Power tools make tough jobs easier—but without the right safety features, they can also create serious risks. That's why modern tools often come with smart built-in systems designed to protect both the user and the machine.

In this article, we'll explore three essential safety features you should look for in any power tool: Leakage Protection (PRCD), Power-off Restart Protection, and Safety Clutch.

1. Leakage Protection Switch (PRCD)

PRCD = Portable Residual Current Device

This small but powerful component is usually placed between the plug and the power tool, acting like a personal circuit breaker.

It constantly monitors the electrical current, and if it detects abnormalities—like current leakage or grounding faults—it automatically cuts off the power.

Why it's important:

Prevents electric shock;

Reduces fire risk;

Especially important in wet, dusty, or high-risk environments

Adds a layer of protection that regular outlets may not provide

2. Power-off Protection Switch

This feature prevents your power tool from accidentally restarting after a sudden power loss.

Imagine you're using a tool and the power goes out due to a blackout, loose plug, or unstable voltage. Without protection, the tool might automatically restart when the power comes back—possibly causing injuries or damaging materials.

With a Power-off Protection Switch, the tool remains off until you manually press the switch again.

Why it's important:

Prevents unexpected tool restarts;

Protects the user and work environment

Adds control and safety in unstable power situations

3. Safety Clutch

A Safety Clutch is a mechanical system that disconnects the motor's torque when the tool is suddenly jammed or the torque becomes too high.

For example, if a drill bit hits a steel bar or a mixer gets stuck in heavy material, the clutch automatically disengages the drive, so the motor keeps spinning but the torque doesn't reach your hands.

Why it's important:

Prevents motor damage from overload

Protects users from sudden kickback (e.g., wrist injuries)

Extends tool life and keeps operations safe

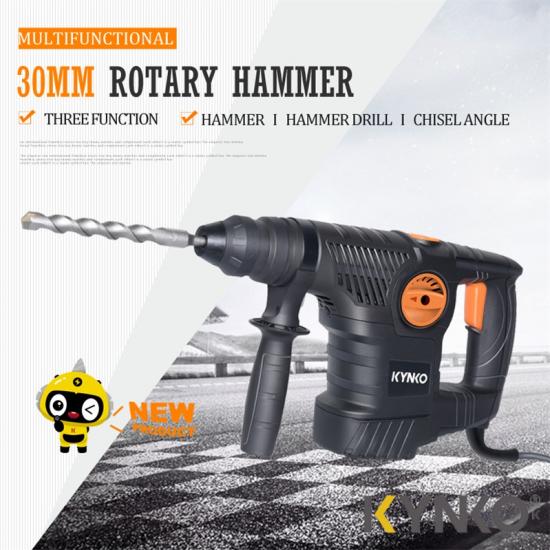

Essential in tools like rotary hammers, mixers, and demolition hammers

KYNKO's Commitment: Building Safer, Smarter Power Tools

At KYNKO, safety is not an afterthought—it's at the core of our product design. We know that professionals need tools they can trust, especially in demanding environments.

That's why many of our tools are equipped with:

①PRCD Leakage Protection – for electrical safety from the source

②Power-off Restart Protection – to avoid accidental tool activation

③Safety Clutch Systems – to prevent injuries and protect the motor

These features can be found in several of our high-performance tools, including: Rotary hammers; Demolition hammers; Electric mixers; Angle grinders; And More.

For example, KYNKO KD68 Rotary Hammer is equipped with Safety Clutch Equipped with a Safety Clutch to prevent kickback, a drop-resistant design, and a quick-change chuck for safe bit replacement. The ergonomic handle and strong 1300W motor ensure power, comfort, and protection during every job.

Whether you're working on construction sites, workshops, or industrial assembly lines, KYNKO tools are built to perform safely and reliably—day after day.

Welcome to contact by Email or Whatsapp to know more safe power tools manufactured by KYNKO :)

Categorías

último blog

Etiquetas

© Copyright: 2003-2025 KYNKO INDUSTRIAL LIMITED Reservados todos los derechos.

IPv6 network supported

Talk by Wechat